SH 9.14 B6

Console with computer, printer, keyboard, 17″ TFT screen and accessories

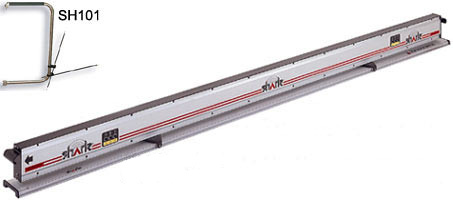

Receiving beam and runway

Mc Pherson SH101

Composition with 6 probes SH102 and adapters

Product description:

- Compatible with all straightening systems

- Measuring of the damages during all the straightening process

- Can be used in diagnosis with a 2 pillar lift

- No moving parts. No wear nor play.

- Automatic and constant verification of vehicle position.

- Measuring of vehicles mechanics in or out.

- No vehicle underbody manipulations required as soon as the Shark is installed.

- Measures up to 12 test points simultaneously every 1,5 seconds.

- Quarterly update of the database on CD-Rom.

- On the screen, possibility of locating some points on photos and drawings.

- Clear symbols. The direction of the deformation is illustrated in 3 dimensions. Evolution during straightening.

- Printed proof of the vehicle dimensions before and after repair.

Technical specifications:

| SH 9.14 B6 | ||

| Width | 650 | mm |

| Depth | 600 | mm |

| Height | 1420 | mm |

| Power | 0,5 | kW |

| Current | 220 | V |

| Weight | 210 | kg |

Accessories

Shark measuring gauge for high test points.

SHF1

Universal brackets

S900U606

Additional kit with 2 probes SH102, adapters and accessories.

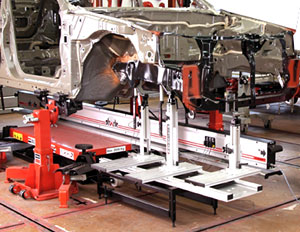

The SHARK® in practice

The Shark used in diagnosis before repair shows all damages including the hidden ones

Shark measuring system used to control pulling operations.

Shark measuring gauge for measuring of high test points.

Set up and fixation of new parts with the Shark and universal brackets SHF1.